TIMET is a company specialized in induction heat treatments: high and medium frequency hardening on steels and cast irons.

Company

In TIMET we consider QUALITY an essential strategic tool

TIMET activity started in the Sixties, thanks to Franco Clementi’s intuition and commitment, and during the time we have continuously optimized our core business.

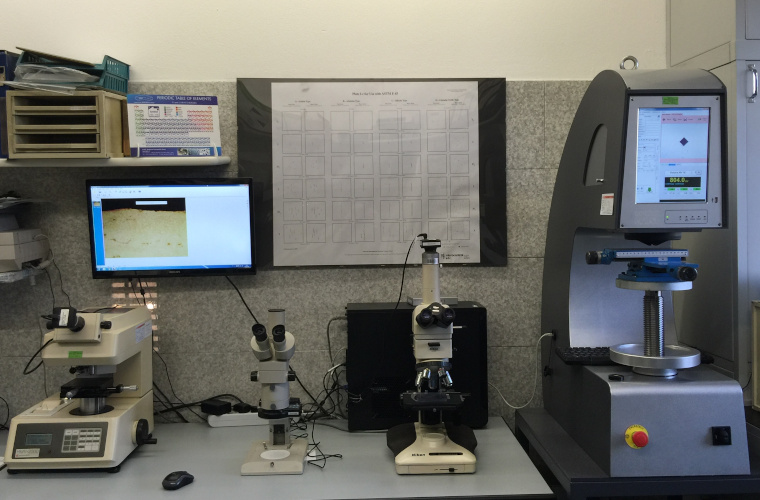

In fact, our company system is in continuous development with the production department equipped with technologically advanced machinery and duly supported by the internal metallographic laboratory, where it is possible to analyze and document the results of the hardening process performed.

In TIMET we consider QUALITY an essential strategic tool to meet the expectations and needs of the customer: control of all stages of processing and verification of achievement of the requirements – updating and continuous training – safety at work and attention to the environment are the cornerstones.

TIMET S.r.l. is certified:

- year 1997 – UNI EN ISO 9002 standard

- year 2003 – UNI EN ISO 9001:2000 standard

- year 2009 – UNI EN ISO 9001:2008 standard

- year 2018 – UNI EN ISO 9001:2015 standard

Induction Hardening

We carry out heat treatment of induction hardening at high and medium frequency and stress relieving after hardening on a very wide range of products, from small parts to large components for machine tools: pallets, cylinders, fifth wheels, gears.

Our technological equipment includes only modern machinery controlled by CNC, allowing us to store multiple processing parameters to ensure the repeatability and traceability over time.

The management of orders on a daily, weekly or even monthly basis is managed in such a way as to be streamlined and this allows us, where there is a particular urgency, to reschedule the sequences of workloads. Collaboration with a constructive attitude and respectful of our customers’ needs.

Lab

We pay particular attention to the controls to be performed in the various stages of processing

In Timet Srl we pay particular attention to the controls to be performed in the various stages of processing by performing tests type Rockwell, Brinnel or Vickers. The control of parts with complex geometries or large size is guaranteed by the provision of portable hardness testers.

We perform non-destructive tests after heat treatment, through the use of liquid penetrants or magnetic particles (with magnetic yoke or magnetoscope bench). For samples or batches numerically relevant we carry out, if required, destructive tests on sample, in order to determine the effective depth of treatment. Internal staff with “Level 2 Certificate” issued in accordance with UNI-EN-ISO 9712.

Timet s.r.l.

Via G. D’Annunzio, 15

20025 – Legnano (MI)

Ph. +39 0331 549479

Fax +39 0331 547682

E-Mail: timet@timet.it

PEC: timet@pec.timet.it

Quote request: commerciale@timet.it

Technical information: produzione@timet.it

Quality: qualita@timet.it

Administration: amministrazione@timet.it